Current Location: Home Page > Main Business > Combustion technology of low NOx pulverized coal

Combustion technology of low NOx pulverized coal

Beijing Guodian dragon tech Environmental Engineering Technology Co. Ltd. as China low nitrogen combustion technology and industrial development led by Harbin Institute of Technology, National Engineering Laboratory and pollutant emission reduction Coal Combustion Engineering Research Institute provides the international first-class development environment and test conditions, and is the only platform of Harbin Institute of Technology Institute of Combustion Engineering of low nitrogen combustion technology industry promotion the uniqueness and exclusiveness in the use of patents.

Our company took part in the demonstration project of Chinese Engineering Institute of Harbin Institute of Technology, Professor Qin Yukun led the Combustion Engineering Research Institute research team for Chinese first national low nitrogen combustion technology (major science and technology project of State Power Corporation), Beijing Olympic Games, Shanghai World Expo, Guangzhou Asian Games and other environmental protection engineering.

Based on more than 150 sets of more than 70 power plant boiler on the transformation experience of our company, the company I used four corner tangential boiler with low nitrogen combustion technology, three-dimensional classification of wall type boiler for swirl pulverized coal combustion technology, W flame boiler with multi ejection staged combustion technology has strong stability, coal combustion adaptability is good, reducing the nitrogen effect, high combustion efficiency, effectively preventing high temperature corrosion and slagging advantages. Among them, the Harbin University of technology research and development of horizontal dense combustion technology is the only to the major boiler plant promotion and application of combustion technology.

Application of three dimensional low nitrogen combustion technology in Harbin Institute of Technology

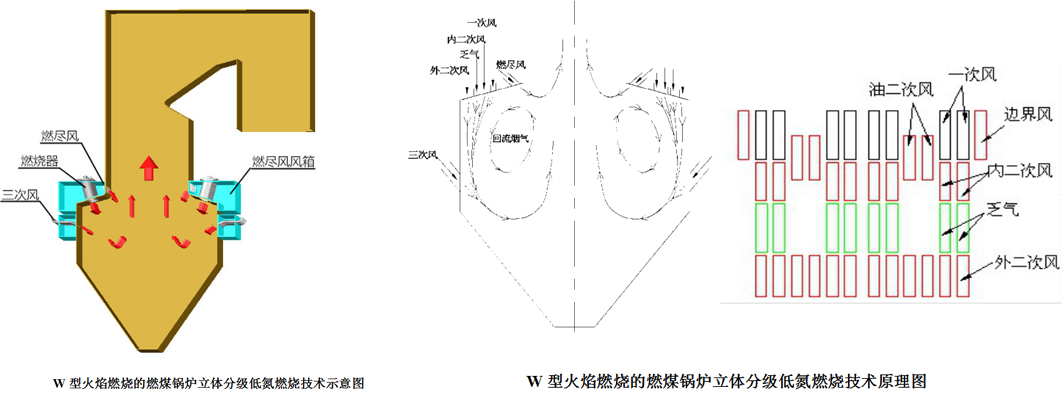

1、Multi stage ejecting combustion technology of "W" type flame boiler

"W" type flame boiler with multi ejection staged combustion technology is in the center of the furnace arch by forward wall are arranged one after the two time in the wind, wind, and wind exhaust gas two times, three times under the arch layout downward wind, arch on vertical section ofa reasonable arrangement.

Make an arrangement of secondary air concentration of pulverized coal in the furnace center near the side, is conducive to timely ignition; by high speed inside and outside the two times and three times the wind wind declination in turn lead a wind down shot velocity is small, so as to obtain the large pulverized coal injection speed, but also achieved gradually with the combustion air supply. The coal burnout and ensure stable combustion; the exhaust gas is arranged between the primary air and the front and rear wall, the bias combustion; two times, three times the wind, wind and wind burn into step by step to achieve a number of staged combustion, can guarantee low NOx emission.

Technological advantage:

(1) excellent low NOx emission performance

Technology and vertical furnace air staged combustion technology combined with stereo staged low NOx emission system formed by the horizontal bias pulverized coal combustion, the NOx reduction rate reached 40%~66%, meet the NOx emission concentration to power plant. Among them, when the high volatile coal is used, the NOx emission index can be reduced to 150~200mg/Nm3; when the medium and low volatile coal is used, the NOx emission index can be reduced to 300~500mg/Nm3. Compared with other technical schools, the NOx emission reduction performance advantages are obvious, especially in the case of burning poor coal, the NOx emission reduction rate can be about 5%~10% higher than other technical schools.

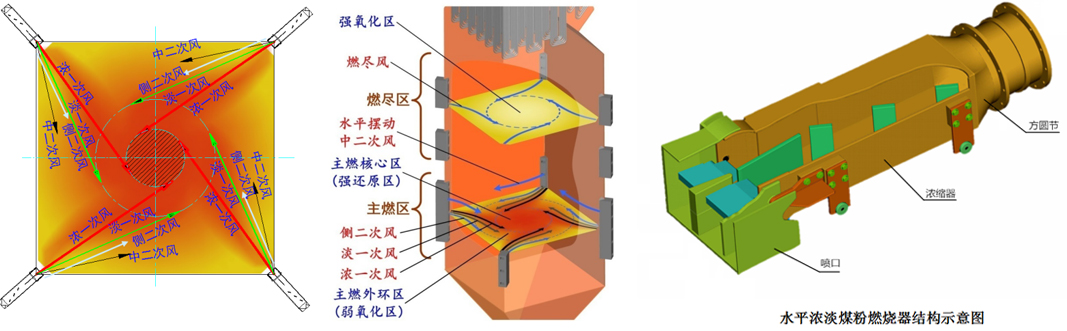

(2) anti slagging and high temperature corrosion prevention effect

"Air bag powder" in the concentrated pulverized coal combustion technology of horizontal bias after grading near the central region of the furnace combustion of pulverized coal, light wrapped in concentrated pulverized coal concentration of pulverized coal flow to the outside, to prevent water wall wall flow, while the light side nozzle has larger two air export momentum side arrangement of fire side, and a light wind near the surface is further reduced with the pulverized coal concentration of water wall, the wall surface oxidizing atmosphere is enhanced, conducive to the prevention of slagging and high-temperature corrosion.

(3) stability of ignition and adaptability of coal quality;

The pulverized coal concentration at the pulverized coal side of the horizontal dense pulverized coal combustion technology is as high as 0.8-1.2 kg/kg, which can ensure the stable operation of the oil under the 30~40%BMCR load for a long time. With the increase of the concentration of pulverized coal, strong combustion stability and high combustion efficiency can be maintained for some low quality coals with low calorific value, low volatility and high ash content. Vdaf in 5% to 50%, Qnet, AR in the range of 2700~6000 kcal/kg can be very good burning.

(4) the control of steam temperature and temperature reduction is reasonable

The horizontal dense pulverized coal combustion technology has the characteristics of early ignition and strong flame stability. It matches with the high burn out air to make the flame center highly suitable, and the smoke temperature at the furnace outlet changes little. The high level of overfire air nozzle design direction + 10 degrees swing, vertical direction + 15 degrees swing, avoid temperaturedifference exports and adjusting the furnace flame centre height, to the great role in the regulation of superheater and reheater outlet steam temperature, the desuperheating water inputs at a reasonable range.

2、Three dimensional low nitrogen combustion technology

Technological advantage:

(1) excellent low NOx emission performance

Technology and vertical furnace air staged combustion technology combined with stereo staged low NOx emission system formed by the horizontal bias pulverized coal combustion, the NOx reduction rate reached 40%~66%, meet the NOx emission concentration to power plant. Among them, when the high volatile coal is used, the NOx emission index can be reduced to 150~200mg/Nm3; when the medium and low volatile coal is used, the NOx emission index can be reduced to 300~500mg/Nm3. Compared with other technical schools, the NOx emission reduction performance advantages are obvious, especially in the case of burning poor coal, the NOx emission reduction rate can be about 5%~10% higher than other technical schools.

(2) anti slagging and high temperature corrosion prevention effect

"Air bag powder" in the concentrated pulverized coal combustion technology of horizontal bias after grading near the central region of the furnace combustion of pulverized coal, light wrapped in concentrated pulverized coal concentration of pulverized coal flow to the outside, to prevent water wall wall flow, while the light side nozzle has larger two air export momentum side arrangement of fire side, and a light wind near the surface is further reduced with the pulverized coal concentration of water wall, the wall surface oxidizing atmosphere is enhanced, conducive to the prevention of slagging and high-temperature corrosion.

(3) stability of ignition and adaptability of coal quality;

The pulverized coal concentration at the pulverized coal side of the horizontal dense pulverized coal combustion technology is as high as 0.8-1.2 kg/kg, which can ensure the stable operation of the oil under the 30~40%BMCR load for a long time. With the increase of the concentration of pulverized coal, strong combustion stability and high combustion efficiency can be maintained for some low quality coals with low calorific value, low volatility and high ash content. Vdaf in 5% to 50%, Qnet, AR in the range of 2700~6000 kcal/kg can be very good burning.

(4) the control of steam temperature and temperature reduction is reasonable

The horizontal dense pulverized coal combustion technology has the characteristics of early ignition and strong flame stability. It matches with the high burn out air to make the flame center highly suitable, and the smoke temperature at the furnace outlet changes little. The high level of overfire air nozzle design direction + 10 degrees swing, vertical direction + 15 degrees swing, avoid temperaturedifference exports and adjusting the furnace flame centre height, to the great role in the regulation of superheater and reheater outlet steam temperature, the desuperheating water inputs at a reasonable range.